New Year = New Challenges

Bigger companies have gone under as selling assets to help debt means you are reducing the overall business value. They one company they sold they still purchase that product which doesn't make sense. Imagine building a company for supply and then having to sell it because you need the cash and then have to now buy that product you owned from the new owners.

When it comes to business I am always optimistic looking for an opportunity to be had as there is always one if you look hard enough. Last year our figures was rather dismal and things need to change and quickly.

February will be two years since my business partner and I took a salary and that cannot continue. The weird thing is the business is great except the supply of raw material is seriously holding us back. The lack of it is the problem and every other company in our sector is in the same position.

This morning my partner and I caught up as I need to know where we stand with SASOL who is our supplier of chemicals. This week we ordered 50 tons and received 20 tons so 40% of where we need to be. Not unexpected as I thought this would continue along this road until at least March.

</center.

</center.

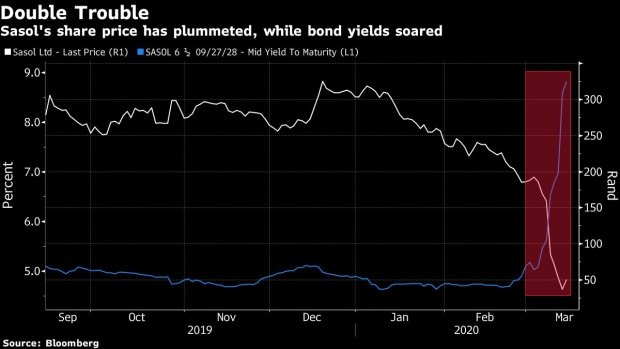

SASOL has a serious debt crisis and even though they reduced that amount last year by $80 million short supply tells another story. They are in big trouble and this is not shortages from lock downs like they keep on saying.

The one good thing is there is a rumor that SASOL our supplier is going under and that would be good news for us anyway. They dominate the local market to an extent they have the monopoly as they are it. Import duties were raised last year to protect SASOL and screwed the entire market. Imports workout at roughly 18% more expensive and that is the profits gobbled up.

SASOL disappearing would pave the way for imports as everyone would be using them and the duties should fall away. If they don't then the price will just have to rise but at least shortages would disappear. Being dictated to what business you can do by what you can purchase is demoralising at the best of times.

The one thing I have learned over the last two years is one has to change the way you think. Business has changed and that means you need to change along with the times. Companies who are our clients are changing and adapting highlighting where you need to now jump or miss out. This is actually a good thing as that means relationships are still key being in on the know.

2022 has some unique challenges that we have to face and praying that our supplier hits the wall maybe a negative, but is actually a positive. Opportunities are there all around us and the idea of having to hold back due to lack of support from a supplier is out of our hands for the time being.

Imagine having 10 clients on hold because you are too scared of letting them down as that is exactly the position we are in currently. I have never known anything like this before and a bit stumped trying to solve this. Diversifying the business away from the stranglehold we are currently experiencing is the only way forward and what we are working on.

Bio degradable plastics is the future in packaging and strangely enough is cheaper and in plentiful supply. This is where our business is heading and will know more within the next month once we have a meet up and bash our heads together. Whatever happens I expect this time next year there will be at least another manufacturing facility in operation or maybe two.

The anti Chinese imports that we have encountered by companies over the last 12 months is bigger than we all think. I believe it is more the global shipping delays forcing companies to stock pile tying up cash reserves is the main reason. This company has 6 months worth of stock taking them up until June/July costing hundreds of millions. Outlaying that capital plus warehousing is eating away at their profits just to guarantee they can continue doing business.

Large global companies in the top 100 have changed buying policies to this effect supporting local manufacture with no imports allowed. The one company mentioned above has started already and will be 100% local come June this year supplying Africa from a central hub about 30 minutes drive away from where I am. This is a trend we cannot ignore and need to make what we do count and adapt.

The truth and reality is no one knows what they might be doing in 6 months from now as there are no constants anymore. Fun and scary times as these are fresh challenges we have never had to face head on like this before. I think this is why certain businesses thrive as they are ready to move when required not being set in stone as the market tells you what direction you are heading.

Most companies that have been around for many years have had to adapt and those that don't will simply vanish. As a business we have to continually evolve whether we like it or not as making money is what counts.

Posted Using LeoFinance Beta

I saw a news story the other night and they said that packing tape is one of the items that are in really short supply in the US right now. Might need some of those packaging engineers to design new containers until they get that sorted out.

This is one of those times you wish you had a machine making tape. Can almost guarantee you this is one item that is 99% imported from China. Brands like Sellotape are all imported and are not locally made.

Posted Using LeoFinance Beta

Interesting!

There you go as there may be an opportunity with Bozz's Sellotape lol.

Posted Using LeoFinance Beta