Exploring the handling and cleaning of industrial equipment Hormainca kiln.

Happy Wednesday, dear hive family.

A few days before the end of February, I am expanding my work experience in the supervision, distribution and marketing of bakery and pastry, which I want to share with you the importance of knowing industrial equipment today with industrial ovens HORMAINCA brand, handling and cleaning.

Family all work has its degree of complexity but between interest and put into practice great learnings are obtained.

I believe that every cultural point is crucial, everything we learn in this life will be an enormous learning that will serve for infinite opportunities, while there is life there is hope.

First of all, each team has a board, which is detailed below:

The people in charge of the oven area gave me a few tips, such as:

Each oven has a brewer and is located at the back of each unit.

When each unit is switched on, the upper display shows the temperature and we can manipulate it according to the type of product required to be displayed at the points of sale.

Then we turn the switch button to turn on the motor being the N# 1, in the following image:

Immediately we visualise that the light at the top shines and as we use the other linear switches they will turn on their lights consecutively.

The number 2 indicates the turn to the tuning peg and the number 3 the air extractor.

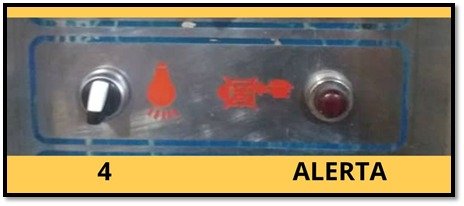

Visualising the board in a descending way we find the number 4, being the light inside the oven, which allows us to see the growth and the tanning of the product, it is important to highlight that once the red button lights up it is synonymous of alert (indicating engine failure).

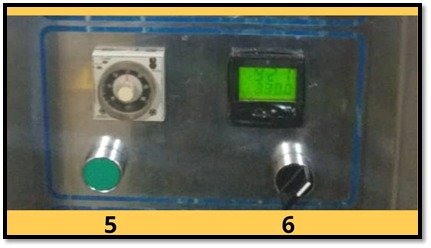

At the same time it has a timer with number 5 corresponding to the steam, and number 6 is the temperature control.

Its cleaning maintenance is weekly, where with the help of a dry cloth and a combination of vinegar and water it is spread all over the equipment, leaving it impeccable.

On the other hand, every three months with the help of osirex, being the oven cleaner effective for removing grease from closed areas.

Corrective and preventive care is as follows:

- The skeleton and plate of the disc are removed for prior inspection. The base of the oven is greased.

- The roller bearings are changed.

- The belts are checked.

- And finally the maintenance of the blowtorch.

This equipment requires an average daily consumption of 250 litres of diesel fuel, which varies according to the rotation of goods.

What do you think of the manoeuvre of this industrial equipment? I look forward to hearing from you in the comments box.

I am pleased to greet you, the photos are my own and I used the deepl translator as my language is Spanish.

!LOL

lolztoken.com

Make me one with everything.

Credit: reddit

@emily22, I sent you an $LOLZ on behalf of osomar357

(2/8)